Specialty Coated Products

For joining plastics

JET Tape™ “J-78 Series”

The acrylic foam-based, double-sided “JET TapeR” is a flexible tape with high adhesive strength, suitable

for a wide variety of industrial applications.

The absence of organic solvents throughout the manufacturing process means that the double-sided JET TapeR

is environmentally friendly.

The “J-78 Series” adhesive tapes are also ideal for joining plastics.

Features

①Double-sided and super high adhesive strength

Simply remove the release paper and press the tape on to the plastic surface to obtain firm

adhesion.

Simple taping operation. No need for welding or other special skills.

②Adapting well to deformation and thermal contraction of materials

being joined

The tape is flexible and elastic, ideal for use on curved surfaces.

The tape is adaptable to thermal expansion and contraction and therefore can be used for joining materials

of different characteristics.

③Adaptability to a wide temperature range

With its high resistance to heat and cold, the tape can be used in a wide temperature range.

The tape can also be used as sealing or vibration-damping material for precision machines.

④Ideal for plastics

The tape also offers high adhesive performance for plastics such as ABS and polycarbonate.

Product range

| Part number | J-78025 | J-7804 | J-7808 | ||

|---|---|---|---|---|---|

| Thickness | mm | 0.25 | 0.4 | 0.8 | |

| Color | White | ||||

| Adhesive strength *1 |

SUS | N/10mm | 12.7 | 16.0 | 21.6 |

| ABS | 6.4 | 10.8 | 12.0 | ||

| Polycarbonate | 10.2 | 15.7 | 19.6 | ||

| Aluminum | 7.8 | 14.7 | 28.2 | ||

| Holding power *2 | N/10mm | 1.7 | 2.0 | 2.5 | |

| Shear strength *3 | N/cm2 | 86.0 | 150.0 | 147.0 | |

Measuring conditions:

- ※1

- The adhesive strength was measured using a piece of BA-SUS stainless steel and a test piece affixed to 50-um-thick aluminum foil. The test piece was affixed to the piece of BA-SUS using a 5-kg roller and was left in position for 72 hours at an ambient temperature of 23°C. The adhesive strength was measured by pulling the test piece at 90° at a velocity of 300 mm/min.

- ※2

- The holding power was measured using a piece of SUS steel and a test piece affixed to 200-um-thick aluminum foil of 25x25 mm. The test piece was affixed to the piece of SUS and was left in position for 20 minutes at an ambient temperature of 80°C. The test piece was then subjected to a load of 2 kg for an hour, after which it was checked for displacement.

- ※3

- Each side of the test piece was affixed to a piece of BA-SUS over an area of 15x15 mm and was left in position for 72 hours. The test piece was then checked for the maximum shear strength under a tensile force of 50 mm/min.

- ※

- The values in the table above are representative of those typically obtained in Soken tests and can vary in actual applications.

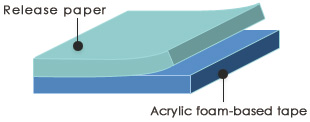

Structure

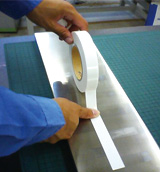

Taping procedure

Clean the surface using solvent or other cleaning agents to remove dirt, rust, oil and other contaminants.

Apply the tape and press it with a finger or a roller to firmly set it in place.

Remove the release paper. Place the joining piece on the tape and press it firmly with a roller or other means.

Applications

・To fix home electric appliance parts

・To fix various materials (metals, plastics)

“J-77 Series” for joining metals

What is JIS Z1541?

“J-78 Series” for joining plastics